Within weeks after installing its new 3-D sand printer, Danko Arlington began sharing this new technology with local students, including mechanical engineering undergraduates from neighboring Johns Hopkins University.

On February 7th 2018, the company hosted Assistant Research Professor of Mechanical Engineering Dr. Yury Ronzhes and his manufacturing class to learn more about this exciting mold making process.

Over the past years, the company has closely collaborated with the Hopkins Baja Racing team and their Teaching Laboratory Manager, Mr. Tom Benassi, to produce cast aluminum car parts made from 3-D FDM printed plastic pattern tooling.

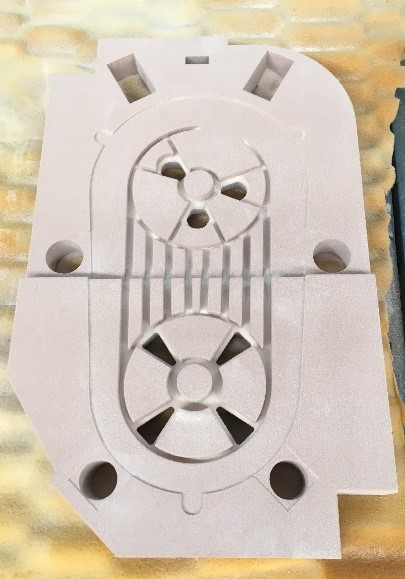

This year’s team and racing captain, Brendan Szuwalski, made a few changes to their previous CVT backplate design. Instead of the making modifications to the old pattern tooling, Danko Arlington was able to use the student’s revised CAD to produce a cast part without the need any tooling. In addition to incorporating the design changes, a new mold cavity was printed without draft and without the student’s labor to ram-up the sand by hand.

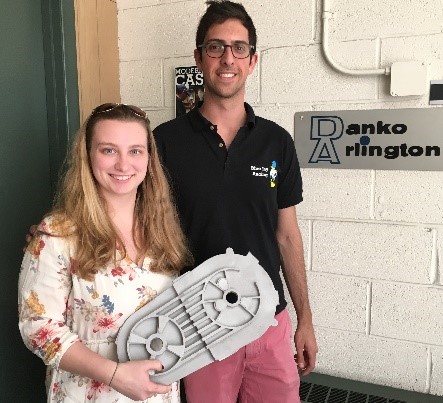

This year’s build process was incredibly fast. During the week of April 9th, the team visited the company to program the 3-D printer on Tuesday, had the mold built on Wednesday, witnessed the part being poured on Thursday, and picked up the new CVT plate on Friday!

The 2018 JHU Baja Team not only has room to boast its use of a casting made with 3-D printed sand, but was able to enjoy a three day lead time – something unheard of in traditional manufacturing. In racing, time is of the essence. Winning is not just being first to cross the finish line, but completing all necessary preparations to get to that finish line before the race begins.

Danko Arlington is proud to showcase its new competitive edge for more win-win outcomes like this one in the race for new products to market.

©2024

©2024