The Use of Additive Manufacturing in Foundry Patternmaking Danko_AMUG2013

(Click on the link to view the Power Point Presentation as a PDF. See the accompanying text below. )

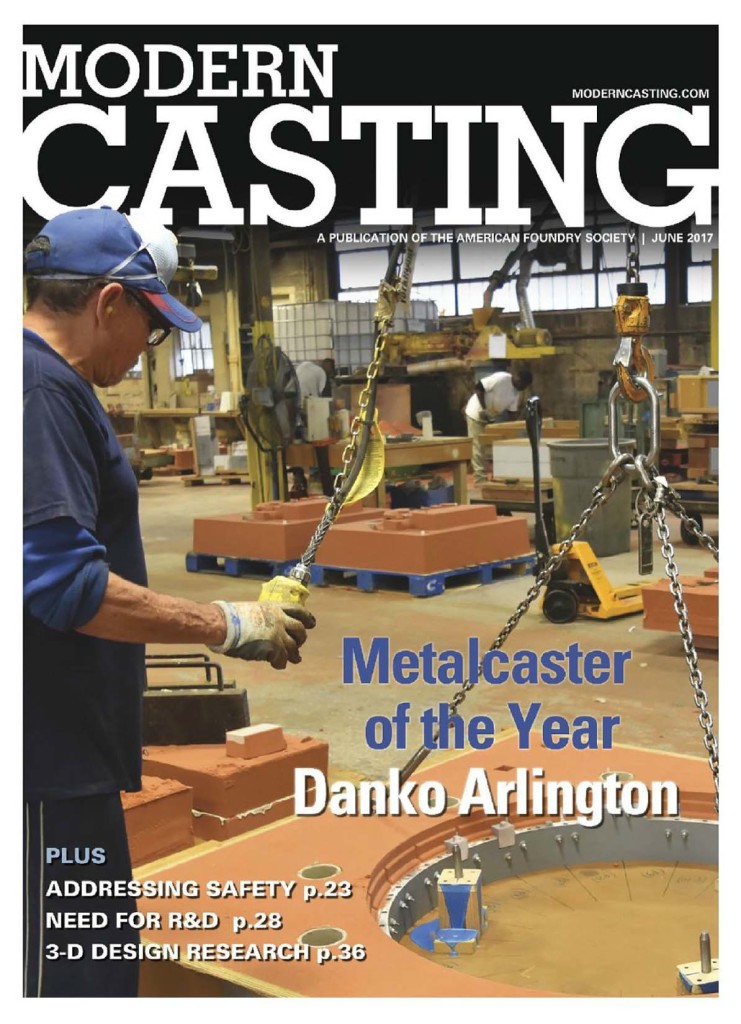

by John D. Danko, President, Danko Arlington, Inc.

2013 Additive Manufacturing Users Group (AMUG) Conference

Jacksonville, Florida, April 17, 2013

Many thanks to Rob Winker from Stratasys for inviting me to share our industry experience. The topic of my presentation this morning is ‘The Use of Additive Manufacturing in Foundry Patternmaking.’’

Let’s start with the assumption that many of you probably do not know what a pattern is. When I tell people that we are in the pattern making industry, many think of making dresses or clothing – making templates out of cloth or fabric. Far from this!

Industrial Patternmaking is the craft of making industrial patterns and core boxes for the foundry industry. An industrial pattern is a form used to create a cavity in the sand mold used for casting molten metal into shapes. The molds used in sand casting process are therefore molds made of bound sand. The pattern is the form used to make the sand mold.

After molten metal is poured in the sand mold, the metal cools, and the molds are broken apart to yield a sand casting. The sand is then recycled and reused with the pattern again to make the next mold, and so on….

Patternmaking therefore is the life blood of the foundry business. Without patterns, foundries cannot make castings. And without new patterns, foundries cannot produce new castings.

Danko Arlington is a ninety three year old manufacturing company which is located in Baltimore, Maryland. The company consists of a not only a pattern shop, but an aluminum casting sand foundry, and a CNC machine shop to finish our castings to tighter tolerances and dimensions.

NAICS Slide

NAICS 332997 Industrial Pattern Making

- Cores, sand foundry, manufacturing

- Foundry cores manufacturing

- Foundry pattern making

- Industrial pattern manufacturing

- Patterns (except shoe), industrial, manufacturing

Earlier this year, while updating our government business profile, we noticed that the North American Industry Classification System (NAICS), or government classification for Industrial Pattern Making, #332997, is now officially obsolete and no longer available in the government database.

NAICS PATTERN MAKING DECLINE CHART CENSUS

Imagine that! After some research, we did see that indeed the number of pattern making businesses has dwindled so much in recent years so that the perhaps this classification is just not worth tracking by the Government. Even though our company still produces patterns, we had to delete this profile from our company description.

Talk about a wake-up call!

There are probably less than three hundred pattern making businesses in the United States now. This data is a sign of the times, as traditional patternmaking is quickly fading away.

So, if the fading away of the NAICS code is any indication of the future of foundries, we foundries are in BIG trouble. Pattern making is necessary to make our products which are sand castings. So without patternmaking and new patterns, we are not going to grow.

Correct? Well yes and no.

Danko Arlington is proof that the foundry industry can indeed move ahead, but only with the use of innovative new technology to replacing an obsolete craft.

As I mentioned, Danko Arlington is now ninety three years old. Three years ago, we embraced additive manufacturing technology as a new opportunity to transform our business which was restricted by a limited skilled labor workforce to now having the ability to expand. As a result, we are now a leader in our industrial sand casting niche.

Before getting into the details about how we have done this, it is appropriate at this point to play a short video about how our company operates to give you the big picture of our entire operation:

VIDEO–Play the video DVD ~5 minutes (the video is also on our website www.dankoarlington.com)

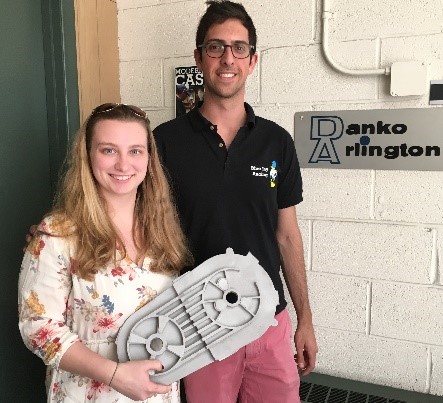

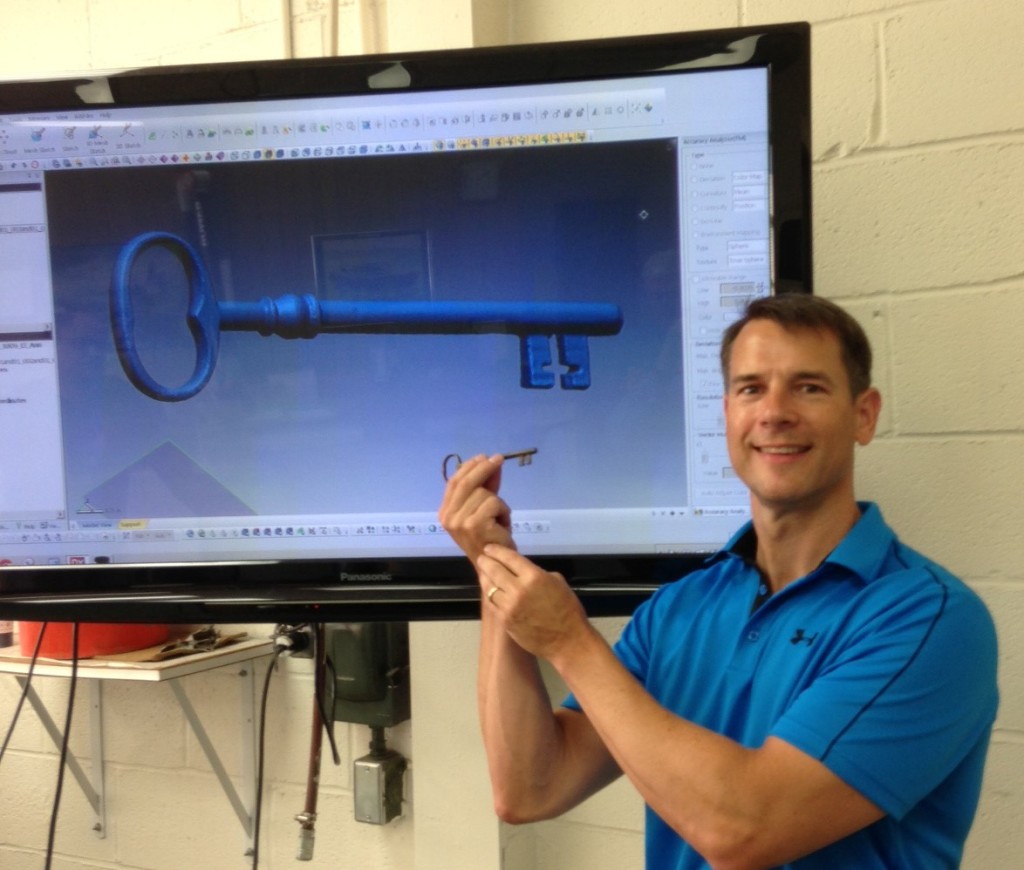

PICTURE WITH FDM PRINT PATTERN

So as you saw in the film, we are now using additive manufacturing to supplement the pattern making division of our business.

At Danko Arlington, our production quantities are often low, so patterns have traditionally been made out of wood, as wood is abundant, cheap, and easily carved. If production quantities are high, patterns are usually made out of metal and cast in a different process known as permanent mold or die casting.

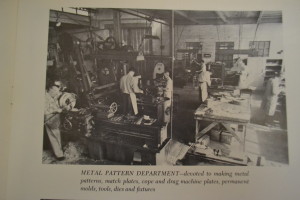

TRADITIONAL PATTERNMAKING PICTURES

My grandfather, Joseph O. Danko, Sr., was a patternmaker, and worked for the Washington Navy Yard during World War I before moving to Baltimore and starting his own business in 1920. At that time, and up to recently, most of the patterns for the foundry were made exclusively by hand in pine or mahogany wood.

One would become a journeyman patternmaker only after many years of experience and training. In fact, the patternmakers in my grandfather’s day were highly regarded as professionals, so much so, that they wore starched collared shirts, neck ties, and white aprons on the job! Pattern makers were never, and should never, be called a blue collar workforce because they were extremely talented individuals who incorporated math, complex geometry, and art in their everyday trade.

Today, with much of America’s manufacturing going offshore, pattern making, and metal casting is a dying trade. The hand-crafted trade is no longer being taught. Many patterns are still made by hand in wood or plastic by near or part-time retirees or being cut out of plastic or metal by computerized CNC machines operated by machinists – another dying trade in the United States. These tasks require very skilled individuals to operate the equipment and program in tool path software such as Gibbs or MasterCam. Good machinists today are very hard to find in Maryland and becoming scarcer by the day.

So how does a foundry that relies on pattern making to mold new cast products stay in business? The answer is to use technology, or in our case, additive manufacturing with 3-D printing, to bridge the gap.

900MC STRATASYS FDM PRINTER

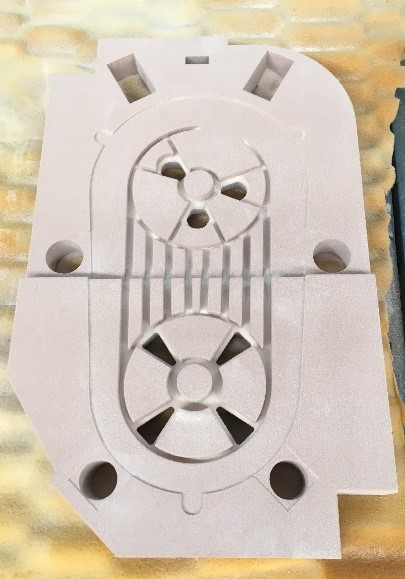

Three years ago, Danko Arlington invested in a Stratasys 900MC FDM printer. FDM stands for fused deposition modeling. Basically the machine uses weed-whacker style spooled high-strength plastic material that is melted layer upon layer on a descending platen until the part is constructed from the bottom up. The 900MC also a maximum build envelope of two feet by three feet by three feet high which allows us to construct a wide range of patterns.

With our hand molding no-bake sand casting process, we are able to use plastic tooling, as our production quantities are usually low and most of the castings we produce parts which fall into the 900’s printer envelope.

We chose a FDM printer configured to use ABS Plastic or Poly Carbonate Plastic. We are using however, mostly the poly carb, or PC-10 material because we needed the strongest printable material we could find to replace the durable hardwoods and urethanes we relied upon for years as pattern materials.

Bear in mind that our molding media, sand, is not only abrasive, but coarse, and heavy, weighing one hundred pounds per cubic foot. So a medium-sized pattern might need to withstand hundreds of pounds of sand weight, in addition to the pressure and impact jolting to ram up the mold and draw out the tool from the sand.

In addition, we are using no bake sand which is a fine silica sand coated with epoxy urethane binders that contain petroleum solvents which can easily soften or melt some plastics that come in contact with the chemicals. The poly carb withstands the corrosion of our particular phenolic urethane system.

The advantages of using the FDM printer are numerous, but here is just a compilation of just some of the benefits over traditional or even CNC pattern making:

PLUS CHART

UNLIMITED NEW DESIGN OPTIONS

What you can envision in Cad Cam design can be easily manufactured. A designer engineer or today’s ‘state-of-the-art’ pattern maker does not need to consider how the pattern is going to be produced. You can print square corners, polygons, odd angles, weird twisted lofted surfaces, reverse angles, or back draft, just for example. Even the most complex shapes can easily be produced as five axis parts with the 3-D printer. The printer only sees layer after layer, so what you can draw, can be made, no matter how complex.

ACCURACY

The printer is extremely accurate in depositing the print material. Our industry sand-cast tolerances are plus or minus 1/32nd of an inch. The printer is accurate within several thousandths of an inch or the width of a couple human hairs. No skilled pattern maker can reproduce these tolerances by hand. This is a huge advantage as closer tolerance tooling obviously produces closer tolerance parts. Closer tolerance parts create less scrap and are often more desired by the customer

INCORPORATION OF LOCKS AND OTHER FEATURES

Features that used to be added after a pattern is made, such as pins, locks, variable fillets, clearances, offset parting, draft, and fillets, are incorporated in the 3-D print job. The idea with using this technology is to keep as much human involvement out of the manufacturing process as possible. Even the best craftsmen make mistakes and additional steps involve a loss of accuracy. It is best to use the printer to do as much as possible as the extra print time should well outweigh the additional hours of labor that would have been involved to finish the project.

EFFICIENT PROCESS

One CAD CAM designer can do the work of several pattern makers! The engineer does not need an office or drawing board, and with a laptop, can do the design work anywhere. Our large tool and die shop has become obsolete and replaced with a 3-D printer – that does not even make any dust! Parts can even be designed at home and later remote downloaded to the printer.

LESS OPERATOR PROGRAMMING AND OPERATOR SETUP

The post processing software to configure a .stl file to print can be done in minutes and the machine can be left alone, unattended to run by itself without having an operator stand by to monitor potential crashes or material clogging.

Creating tool paths in CNC machining, especially five axis machining, is a very time consuming effort. Good machinists are also scarce. As most patterns are unique individual constructions in quantity of one, the setup and programing efforts for CNC machining are a significant portion of the total cost of the job.

FAST

Additive manufacturing has been also referred to as ‘rapid prototyping.’ The ‘rapid’ process is a huge benefit in patternmaking. What use to take weeks to fabricate by human hands now takes days, or sometimes hours to print. Making duplicates of the pattern can be easily done with a touch of a button. If the tool wears out, replacements can easily be made as well.

VERY RELIABLE

The reduction of construction and lead time using FDM printing also correlates to lower pricing and improved scheduling. The print time is quantifiable at the time of design and this data can be relied upon for very reliable planning. You know the hour and minute the job is coming off the machine, independent of someone not showing up for work, for example. The reduced lead time is a tremendous seller and puts your company well ahead of the competition. In many cases, we can charge premiums for increase profit for quicker lead times.

GREAT SALES TOOL

We are even using the additive technology in the bidding phase of contracts as R&D modeling tool well. For large or complex bids, we are able to provide better pricing to customers if we spend some time during the proposal stage printing the full scale part needed to be cast. In this way, we are able to get a better feel of the design than just reading a two dimensional blueprint.

Our managers then have better confidence and estimate with more accuracy and with less material than just taking an educated guess. And speaking about the competition, there is nothing like sending that prototype part which you made during the bidding stage with your proposal. We find that our customers are blown away and eager to do with a company that had done their ‘homework.’

CHALLENGES CHART

EQUIPMENT COST

The 900MC is a high cost FDM printer and a substantial investment for an average pattern shop. Most shops are small businesses with only several employees. The investment to bring on a huge piece of capital equipment is also a great risk, particularly for the job-shop industry which has its ups and downs. Smaller printers don’t work well for construction of larger patterns. There are smaller print envelop printers available at significant less cost, but that would entail joining smaller pieces together. Our experience in joining small printed pieces has not been successful. Recall that we are talking about hundreds of pounds of sand material that often is rammed under pressure, so the less joints that can become loose, the better.

MATERIAL COST

As compared to other materials to construct patterns such as wood, plastic, or metal, the poly carb FDM material is very expensive. In the old days, when our patterns were exclusively made of wood, we accounted for the material in board feet – this is standard in lumber mills today. One board foot is the volume of wood which is twelve inches wide by twelve inches long by one inch thick. Clear white pine and mahogany woods are scarce today, so we use poplar wood. One board foot of poplar is about $4.00 today. The same volume for a RENSHAPE plastic board would cost around $ 22.00, and the same size in aluminum 6061-T6 plate would cost, depending on quantity, about $35.00. A solid chuck of Poly Carb (material only) printed in the same size would cost over seventeen times the amount of the aluminum, almost thirty times the Ren-shape, one hundred and fifty times the poplar wood! So, to keep costs down, we only print as much as we need. Often time, our FDM patterns are similar to inserts. Our patterns are therefore hybrids of the print material and traditional materials such as plywood, repro, urethane, and other materials. We only print as much as we need.

As I mentioned before, at present, it is cost prohibitive for constructing large patterns using additive manufacturing. In addition to increase costs, large patterns would take weeks of print time for laying down both build and support material. Unless you have more than one printer, most users will be mindful of tying up their machine for weeks for one job. Stratasys has a terrific program called Red Eye, however, which you can use to print excess capacity, but obviously, you would have to contact them for pricing on these additional builds and add the costs to your project. So each pattern shop or foundry, depending upon the complexity of their castings, must find a break even size or shape when to go to CNC machining, example, for a pattern made of wood or foam for reasonable cost and lead time.

Like all things over time, perhaps the printing materials will come down in price.

FRAGILE DESIGNS CAN TWIST

Thin pattern designs: Due to high material costs, build time, and increased through put, the goal is to make as thin a pattern and core boxes as possible. Thinner patterns require less material and build faster. Obviously, if there is only one casting needed, the pattern can be made basically a throw away versus make a solid pattern for thousands of impressions. Overall, the foundry must take this into consideration when using the FDM tooling. Personnel also need to be re-trained that this stuff is delicate and not to beat it hard with a hammer, for example.

Pattern distortion can also occur sometime immediately after the FDM is printed. We have noticed this particularly in thin-walled patterns with crazy geometries. The FDM is printed inside a hot environment in the printer, and when some plastic shapes are removed from the heat and placed in room temperature, one can hear popping sounds as the part cools.

After the part is removed from the build sheet and placed on a flat granite surface plate, for example, many times there is a small gap between the flat surface and the part. Obviously when the FDM pattern is fastened down to a pattern board, the twist comes out. The trick is to properly line up the patterns to compensate for the twist to come out when the pattern is assembled.

FRAGILE DESIGNS CAN CRACK IF MISHANDLED OR STRESSED

Unfortunately thin plastic patterns can crack. The side effect of thin patterns also sacrifices strength. Many of our earlier patterns have cracked over several months of usage in the foundry. We have attributed this to flexing during the molding and stripping process that patterns must endure. If the FDM pattern is fastened too tightly to the board, the shape will crack as well, propagating from the screw holes and countersinks throughout the entire piece. The pattern will eventually fracture and start coming off of the board. The solution is to make thicker, more solid patterns than as originally designed. Again, this is a cost vs. usability balance which each user must assess for each application.

FDM PATTERNS ARE DIFFICULT TO REPAIR OR MODIFY

It is very difficult to modify or repair FDM patterns. Unlike wood patterns, it is difficult to modify or repair FDM patterns. With wood, you can use body putty, glue, or even tack shim stock to worn or damaged patterns. This is particularly challenging for FDM patterns as nothing sticks to this stuff. We have used solvents putty and even hot glue. You are better off reprinting the job all over again. If the pattern has any flex to it, the repairs are going to pop off like scabs. Again, the changes are not worth it, rather reprint pattern with new file.

CHEMICAL SAND BINDERS CAN DEGRADE PLASTIC TOOLING

In addition to cracking, chemical binders or paint can weaken the pattern causing failures. There are dozens of chemical binders or foundry glues to bind the sand together today. Design engineers therefore must be aware of the foundry’s system for potential corrosive contact with the pattern surface. Mold release agents which are sprayed on the pattern must also be considered. Foundries that use green sand, which is clay mixed with water, a binder, should not have problem. However, unlike the no-bake process, green sand must be squeezed together under great pressures to activate the clay bonds and the high pressures might cause cracking of printed patterns that are not made solid. In addition, we have found that our primer paint which we used for finishing the FDM patterns contained a solvent called toluene which degraded the surface of the plastic.

THERMOPLASTIC PATTERNS CAN DISTORT IN HOT SAND

Hot reclaimed sand might distort FDM patterns. Design engineers should also be aware that many foundries use sand reclamation to recycling spent foundry sand. This can be mechanical and/or thermal reclamation. Often this sand can be warm or even hot, especially if the sand was being used as a medium to pour steel or iron. At present, metal tooling is used for these patterns and obviously thermoplastic patterns when heated may distort and fail.

FDM PATTERNS AND CORE BOXES REQUIRE HAND LABOR AND FINISH

And finally, and, at present, the biggest obstacle for us is the post finishing of the FDM patterns. This is a necessary labor intensive process. Recall that we were trying to omit all labor using additive manufacturing in the first place! Fortunately, the scarce skills of a pattern maker or machinists are not required, but you really need to have someone who knows what they are doing, or patterns will be ruined.

The post finishing includes hand sand/finish all molding surfaces to rid the printer build layer ridges. If the pattern is not slick and smooth, it will not release from the sand, or if it does come out, the surface causes sand to tear during stripping also known in the trade as ‘cat scratches.’ Any type of scratch in the mold will appear in the casting and would be cause for a casting rejection.

We have used the vapor smoothing process for ABS plastics and found it to be pretty random and unpredictable. It is good for cosmetics, but not consistent in accuracy and uniformity. Some surfaces can erode faster than others and close tolerances can be affected. Poly Carbonate material is not affected with vapor smoothing, but as an alternate, we have tried immersing the pattern in a vibratory mill. Vibratory mills use small stones which are contained in a jiggling tub which tumble and roll around part surfaces. Although this does smooth out surfaces, it is not consistent, and some surfaces can be abraded more than others.

So, we are basically using hand sanding and blue bondo auto putty filler. We are filling all the ridges with this polyester material, then hand sanding smooth. If the technician sees zebra stripes, then we are pretty close to a nominal dimension. Too much putty is a common problem. If your tolerances are +/- .020, and you are sanding a little too much, you are going to lose your part tolerances just in the tool. Again, the goal of the tool is to make the part as close to nominal as possible, thus saving the tolerances for the casting processes, which including molding, grinding, and straightening.

A side effect of the filler is that the bondo can peel off of patterns causing scabs which appear on the castings. If this is caught too late, you have a batch of bad castings. The pattern repair, and down time are also negatives for meeting tight delivery schedules.

In summary, even though many foundries pour the same alloy, their processes, tolerances, and products, large or small, can require a variety of pattern construction. Design engineers making new patterns therefore must take into account all of these for a best fit.

We are confident that the challenges (not really minuses) can be overcome with knowledge and experience, particularly as these additive manufacturing is becoming more affordable.

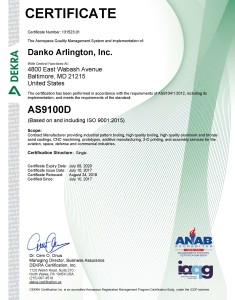

DANKO ARLINGTON SLIDE

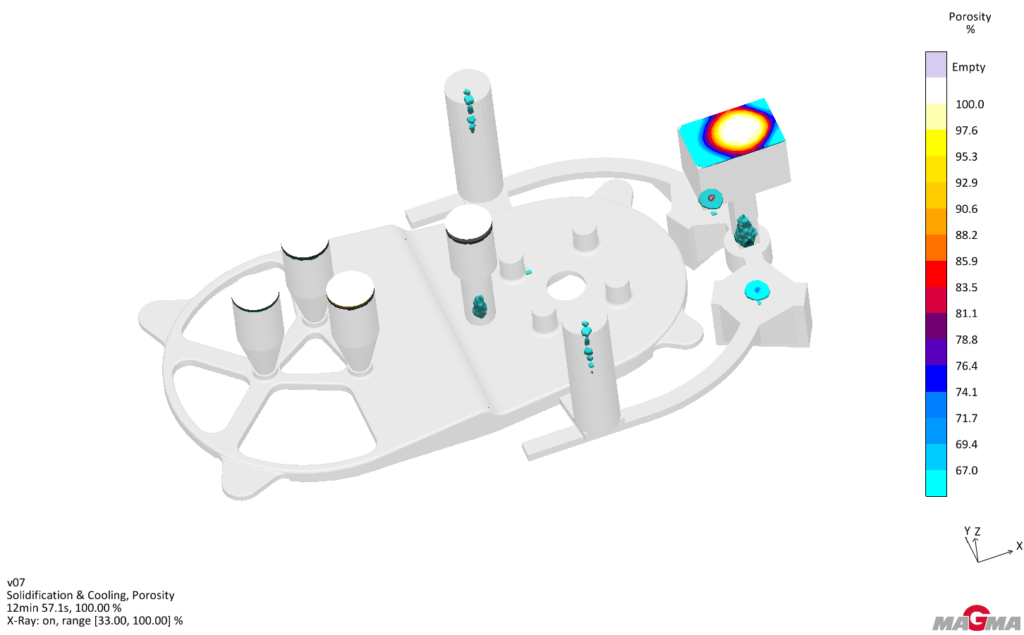

For Danko Arlington, FDM printing for our company is a GREAT fit, particularly as we specialize in smaller quantities, in small to medium sizes with tightly tolerance x-ray grade castings for commercial and military applications.

The use of additive manufacturing for industrial pattern making has provided greater throughput in producing tooling. More tooling means more work for our foundry molders, grinders, machinists, administrative, and sales people. The rapid technology has been a huge job catalyst that can cause a factory to come alive.

This trickle down, positive effect, also makes the current high cost of this technology more palatable. In our case, for example, we are just not growing and investing in our patternmaking business, but our company as a whole. Justifying an expensive capital equipment purchase is extremely difficult, especially in this bad economy, but with the justification for company- wide expansion the investment risk is more palatable.

We are still in an R&D stage even after using this technology for the past two years. We are working through the bugs at present with help from Stratasys for optimizing FDM tooling for our sand casting process.

Finally, I should mention that we have actually been hiring new employees due to our use of additive manufacturing. Let me repeat, Danko Arlington — a Maryland manufacturer in an old fashioned primary metals business with SEVEN smoke stacks has been hiring!! If you remember nothing else today remember that because of our use of additive manufacturing, Danko Arlington is hiring!

I am happy to share our story with you and inspire your creativity as well. Additive manufacturing is incredibly exciting and hopeful for rebounding American business like ours.

We often refer to our business as foundry ‘’practice.’’ We say ‘practice’’ like law and medical practice, because we are never perfect, and always seeking improvements.

Similarly, the use of additive manufacturing is not perfect at this point, but it is very promising. We are confident that through networking and conferences such as this 2013 AMUG meeting, that we can share our ideas to reach that perfect application.

In the interim, I wish all of you continued success in your entrepreneurship and future ventures as well! Many thanks again for the opportunity to present!

Danko Arlington has relied on the talents of craftsmen for decades. Specializing in industrial patternmaking for both military and commercial contractors since 1920, the manufacturer was one of the first in Maryland to grow its own skilled workforce by offering apprenticeships. Over the years, Danko trained many Baltimore locals and immigrants alike as tool and die makers, skilled in making the company’s aluminum and bronze sand castings by hand.

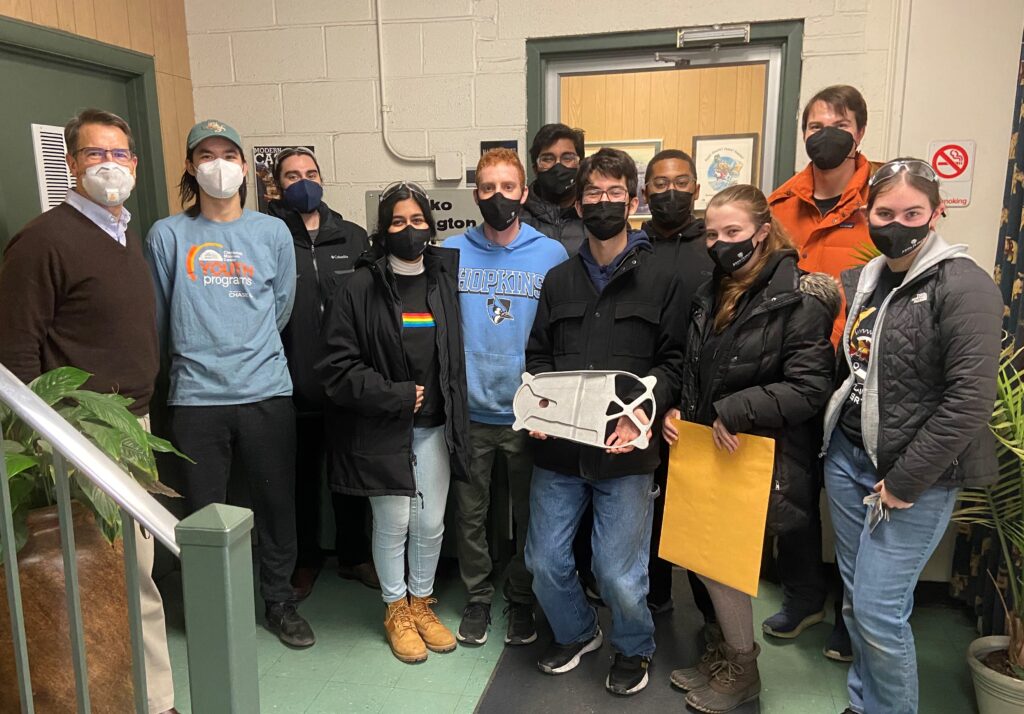

Danko Arlington has relied on the talents of craftsmen for decades. Specializing in industrial patternmaking for both military and commercial contractors since 1920, the manufacturer was one of the first in Maryland to grow its own skilled workforce by offering apprenticeships. Over the years, Danko trained many Baltimore locals and immigrants alike as tool and die makers, skilled in making the company’s aluminum and bronze sand castings by hand. With guidance from MD MEP, Danko created a new four-year, 8,000-hour apprenticeship program that will train workers as CNC Machinists, with skills in 3D printing, CAD, and the robotics needed to cut parts using machine tools. Apprentices will undergo a combination of hands-on training and classroom hours, which will be completed virtually using the Tooling U-SME online platform.

With guidance from MD MEP, Danko created a new four-year, 8,000-hour apprenticeship program that will train workers as CNC Machinists, with skills in 3D printing, CAD, and the robotics needed to cut parts using machine tools. Apprentices will undergo a combination of hands-on training and classroom hours, which will be completed virtually using the Tooling U-SME online platform.

Danko Arlington is very pleased to participate in the BGE Small Business Lighting Solutions Program. This environmentally green initiative is a result of the EmPOWER Maryland Energy Efficiency Act of 2008 which legislates lower energy demands including a 15% reduction of per capita consumption by 2015.

Danko Arlington is very pleased to participate in the BGE Small Business Lighting Solutions Program. This environmentally green initiative is a result of the EmPOWER Maryland Energy Efficiency Act of 2008 which legislates lower energy demands including a 15% reduction of per capita consumption by 2015. Danko Arlington Inc., a Maryland Corporation, is honored to have been selected by the US Naval Facilities Engineering Command (NAVFAC) to cast two historic anchor replicas flanking the main entrance of the Washington Navy Yard located in Southwest Washington DC. The gate is listed on the National Register of Historic Places.

Danko Arlington Inc., a Maryland Corporation, is honored to have been selected by the US Naval Facilities Engineering Command (NAVFAC) to cast two historic anchor replicas flanking the main entrance of the Washington Navy Yard located in Southwest Washington DC. The gate is listed on the National Register of Historic Places. President Thomas Jefferson appointed the famous American architect Benjamin H. Latrobe to design the gate which was completed in 1806. Latrobe’s innovative use of a Greek revival design was one of the first structures at the Navy Yard. Interestingly, Dr. William Thorton, a competing architect at the time and designer of the US Capital, criticized the gate as “a monument to bad taste and design,” and that the anchors were “fitter for a cock boat than a gun boat!”

President Thomas Jefferson appointed the famous American architect Benjamin H. Latrobe to design the gate which was completed in 1806. Latrobe’s innovative use of a Greek revival design was one of the first structures at the Navy Yard. Interestingly, Dr. William Thorton, a competing architect at the time and designer of the US Capital, criticized the gate as “a monument to bad taste and design,” and that the anchors were “fitter for a cock boat than a gun boat!” The structure escaped being burned down when the British sacked the capital during the War of 1812. Although modified through the years, the gate has the reputation of being the oldest continuously manned post in US Navy and currently serves as a ceremonial entrance for the US Chief of Naval Operations and flag officer who reside at the Yard. The original anchors were hand carved out of wood and are now housed at the National Museum of the United States Navy located at the Navy Yard. The replica anchors were created by digitally laser scanning the historic originals in to a computer file from which a new design was superimposed. The new geometry was then used to make foundry molds to cast durable, lightweight, solid aluminum anchors which were later painted gold. They were installed on April 7th, 2010.

The structure escaped being burned down when the British sacked the capital during the War of 1812. Although modified through the years, the gate has the reputation of being the oldest continuously manned post in US Navy and currently serves as a ceremonial entrance for the US Chief of Naval Operations and flag officer who reside at the Yard. The original anchors were hand carved out of wood and are now housed at the National Museum of the United States Navy located at the Navy Yard. The replica anchors were created by digitally laser scanning the historic originals in to a computer file from which a new design was superimposed. The new geometry was then used to make foundry molds to cast durable, lightweight, solid aluminum anchors which were later painted gold. They were installed on April 7th, 2010.

Danko Arlington was saluted at a Christmas party held by Episcopal Community Services of Maryland on the 16th of December, 2009, at the Emmanuel Episcopal Church in downtown Baltimore City.

Danko Arlington was saluted at a Christmas party held by Episcopal Community Services of Maryland on the 16th of December, 2009, at the Emmanuel Episcopal Church in downtown Baltimore City.

Danko Arlington is honored to be awarded the Gaudenzia Employer of the Year for 2008.

Danko Arlington is honored to be awarded the Gaudenzia Employer of the Year for 2008. Danko Arlington was recognized by Episcopal Community Services of Maryland on June 5th, 2008, at a special breakfast held at the Church of the Redeemer in Northern Baltimore City.

Danko Arlington was recognized by Episcopal Community Services of Maryland on June 5th, 2008, at a special breakfast held at the Church of the Redeemer in Northern Baltimore City.

Danko Arlington expanded its foundry and machine shop operations in March, 2008.

Danko Arlington expanded its foundry and machine shop operations in March, 2008. Danko Arlington showcased several of its production castings at the Solidworks Solidworld software convention held in New Orleans from February 4th -7th, 2007.

Danko Arlington showcased several of its production castings at the Solidworks Solidworld software convention held in New Orleans from February 4th -7th, 2007. Danko Arlington was honored to cast an exact replica of an antique Celtic bronze cross for Baltimore’s St Andrew’s Christian Community.

Danko Arlington was honored to cast an exact replica of an antique Celtic bronze cross for Baltimore’s St Andrew’s Christian Community. The skilled metal working personnel at Danko Arlington joined hundreds of local craftsman to renovate and restore Baltimore’s Basilica Church, officially known as the Basilica of the National Shrine of the Blessed Virgin Mary – America’s First Catholic Cathedral.

The skilled metal working personnel at Danko Arlington joined hundreds of local craftsman to renovate and restore Baltimore’s Basilica Church, officially known as the Basilica of the National Shrine of the Blessed Virgin Mary – America’s First Catholic Cathedral. Danko Arlington assisted the American Metal Casting Consortium (AMC) by providing class room training and a foundry tour on July 25th, 2006 for selected employees from the Defense Supply Center in Richmond, Virginia.

Danko Arlington assisted the American Metal Casting Consortium (AMC) by providing class room training and a foundry tour on July 25th, 2006 for selected employees from the Defense Supply Center in Richmond, Virginia. On April 5, 2006, Danko Arlington acquired Patterns Unlimited – an industrial pattern shop specializing in metal patterns and core boxes used by large automated green sand foundries. The shop specialized in CNC machined iron and steel patterns used on Hunter, Disamatic, and Osborne equipment, as well as cast iron Shalco, Redford, and Demmler core boxes.

On April 5, 2006, Danko Arlington acquired Patterns Unlimited – an industrial pattern shop specializing in metal patterns and core boxes used by large automated green sand foundries. The shop specialized in CNC machined iron and steel patterns used on Hunter, Disamatic, and Osborne equipment, as well as cast iron Shalco, Redford, and Demmler core boxes. Maryland Governor Robert L. Ehrlich visited Danko Arlington on January 20th, 2006 to personally present a State Citation for the company’s efforts for working with faith-based organizations to rebuild Maryland’s workforce.

Maryland Governor Robert L. Ehrlich visited Danko Arlington on January 20th, 2006 to personally present a State Citation for the company’s efforts for working with faith-based organizations to rebuild Maryland’s workforce. Danko Arlington. was a 2005 recipient of the Mayor’s Recognition Awards presented by Baltimore Mayor Martin O’Malley and the Greater Baltimore Committee for demonstrating significant corporate leadership and service for improving the quality of life in Baltimore City.

Danko Arlington. was a 2005 recipient of the Mayor’s Recognition Awards presented by Baltimore Mayor Martin O’Malley and the Greater Baltimore Committee for demonstrating significant corporate leadership and service for improving the quality of life in Baltimore City. On March 26, 2005, Joseph O. Danko, Jr., Chairman of a family-owned foundry, pattern, and machine shop business started by his father in 1920, died after a short battle with cancer at his Baltimore home in Homeland. He was 78.

On March 26, 2005, Joseph O. Danko, Jr., Chairman of a family-owned foundry, pattern, and machine shop business started by his father in 1920, died after a short battle with cancer at his Baltimore home in Homeland. He was 78.

On February 28, 2005, Danko Arlington’s Pattern Shop Superintendent, Mr. Howard Goodrich, celebrated 50 years working in the company.

On February 28, 2005, Danko Arlington’s Pattern Shop Superintendent, Mr. Howard Goodrich, celebrated 50 years working in the company. Danko Arlington was honored as the 2004 Employer of the Year by the Baltimore Associated Jewish Charities’ Jewish Vocational Service. The company was formally recognized by the agency’s President, Mrs. Nancy Gertner, and the Executive Director, Dr. Jennie Rothschild, at the annual meeting held on May 13th, 2004 at Beth El Congregation.

Danko Arlington was honored as the 2004 Employer of the Year by the Baltimore Associated Jewish Charities’ Jewish Vocational Service. The company was formally recognized by the agency’s President, Mrs. Nancy Gertner, and the Executive Director, Dr. Jennie Rothschild, at the annual meeting held on May 13th, 2004 at Beth El Congregation. Danko Arlington hosted ninety five Midshipmen from the US Naval Academy on February 18th, 2004. The plant tour was part of the Academy’s Material Science Class EM313 predominately for 2nd Class (Junior) Mechanical Engineering majors.

Danko Arlington hosted ninety five Midshipmen from the US Naval Academy on February 18th, 2004. The plant tour was part of the Academy’s Material Science Class EM313 predominately for 2nd Class (Junior) Mechanical Engineering majors.

©2024

©2024